Sidor could produce the greenest steel in the world at a cost 50% lower than the global average

The Iron-Steel Sector in Venezuela

November 15, 2022The country can produce 30 million tons/year of iron and 17.8 million of liquid steel, which translates into a profit of 20.317 million dollars and the creation of 138,100 jobs according to a study.

06/22/2023 02:29 PM | By Laura Clisánchez / Photo: Correo del Caroní

https://www.bancaynegocios.com/acero-hierro-sidor-palogrande/

Venezuela has, in one place, all the possibilities to produce the greenest steel in the world with one of the most competitive production costs in the international market in the face of new global trends to reduce the carbon footprint in steel production. That place is Guayana.

Three elements make it possible: high-quality mineral deposits, the Caroní hydroelectric power and low-cost natural gas. Its production does not depend on coal and coke as fuels, because it uses electric arc furnaces and direct reduction in its processes.

Consequently, the amount of CO2 it emits per ton of steel does not exceed 800 kilograms.

A steel business

In figures, how much profit can you generate? Venezuela has the capacity to produce at low cost 30 million tons of iron in direct reduction plants and 17.8 million tons of liquid steel per year.

This potential translates into an estimated profit of $14.4 billion from steel alone, and $20.317 billion from ore to rolled steel.

In addition, it means the creation of 138,100 direct and indirect jobs.

Although the state of the iron and steel industry is not optimal at present, it has potential and qualified human resources. It continues to be the country’s non-oil economic alternative.

The production of pellets alone, for example, has a potential of 30 million tons per year with a value of 5.7 billion dollars. Besides that it can generate 2,500 direct and indirect jobs.

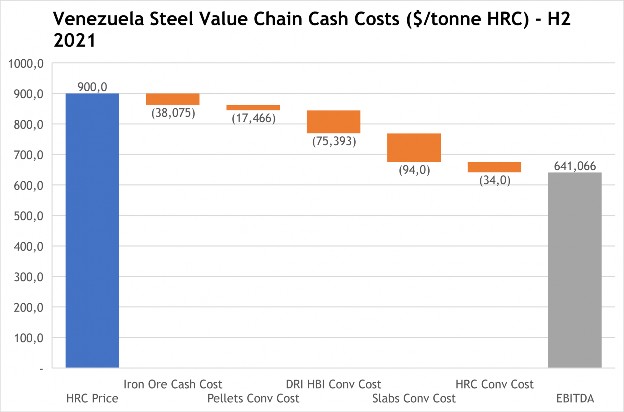

In theory, the Siderúrgica del Orinoco “Alfredo Maneiro” (Sidor) could produce at a cost of less than 300 dollars per ton of steel. 50% lower than the estimated world production, which is between 500 and 600 dollars per ton of hot rolled coil, a figure that varies depending on the country.

Business plan for steel

These figures are the result of a study coordinated by a group of specialists called “Guayana and its Future” with members of Palogrande Casa de Bolsa, an investment banking firm that proposed a public policy proposal or business plan for the steel sector of Venezuela, whose assets are currently under state control.

In general terms, the proposed business plan aims to optimize the value of these assets and new investments for current and future stakeholders.

Estimates indicate that this potential could be realized in a period of five years with an investment of 5,000 million dollars, if the political conditions change and the statist management model of the industry is modified, so that the private sector takes the reins. of process.

Thanks to Guayana, Venezuela has an advantage

Currently, 67% of the world’s steel production uses blast furnaces, that is, its process requires coal and petroleum coke as fuels for ferroalloys, which emits large amounts of CO2 into the atmosphere.

The steel industry represents 8% of CO2 emissions worldwide. Given the global trends of environmental commitment against climate change, this sector will be forced to make the transition towards the greenest of existing technologies.

In other words, the most important challenge facing steel producers in the world is how to decarbonise their production.

“If you have a blast furnace and you don’t have access to natural gas or other resources like hydroelectricity, you can’t solve the problem. There are few places in the world that have the natural conditions to produce steel like those of Venezuela,” says engineer Víctor Vásquez, one of the managing directors of Palo Grande Casa de Bolsa, and coordinator of the study, in an interview. with “Banca y Negocios”.

Venezuela, with its steel production potential, emits less than 800 kilograms of CO2 per ton of steel. Why? Because it does not use blast furnaces (coal and coke as fuel) for its process, but electric arc and direct reduction furnaces.

“There are additions of a certain type of high purity coal (anthracite) to make the pellets that are placed in the electric arc furnaces, but it is a minimal amount of coal. The world average is 1.7 tons of CO2 for every ton of steel produced. In Venezuela we are below 800 kilograms per ton of steel, with direct reduction plants being the largest emitters,” argued Vásquez.

The study highlights that the goal that the world industry has established for 2050 is to reach 600 kg of CO2 per ton of steel. And Venezuela can get to that even before 2030.

The little CO2 emitted by steel can be captured and used

Vásquez points out that, in addition to emitting a minimum amount of CO2, it can be captured, stored and used to optimize the oil industry.

“It is feasible from a technical point of view because, in addition, we have something that no one else has and that is where we put the CO2. We have plenty of space to store CO2 and use it for improved oil production. If we did that, we would be below 300 kilograms of CO2 per ton of steel,” he said.

“Since these plants consume natural gas to transform hydrogen into carbon monoxide to remove oxygen from iron oxide, they emit CO2, but, in this process, capturing CO2 is easier, when you have such high production volumes it becomes more cheap to take it to places where you can use it. In the light crude oil deposits, southern part of Monagas and Anzoátegui, for example”, he pointed out.

The capacity that Venezuela has to store and use the CO2 emitted, in the opinion of the specialist, is the icing on the cake because new technologies are currently being explored in the world to produce CO2 more cleanly and reduce emissions.

CO2 is used in the oil industry to increase production and rejuvenate reservoirs, through the injection of CO2 into oil and gas fields. CO2 is injected into wells to increase pressure and push up the remaining oil, allowing more to be extracted.3

Is the proposal applicable in the medium term?

It depends on several factors, mainly political. Before its nationalization, Sidor produced 4.5 million tons of liquid steel, when it was under the administration of the Italian-Argentine transnational Techint.

Then, in 2008, former President Hugo Chávez nationalized the Re and from that year its production began its free fall until it reached zero in 2019, its most critical point, due to government mismanagement.

By 2020, the once most important steel mill in Latin America and the Caribbean, registered a production of just 17,000 tons of liquid steel, that is, less than 1% of its installed capacity.

CVG Ferrominera Orinoco also produced 22 million tons of iron.

“Until the end of the 1990s, it was possible to transform and add value within Venezuela to 64% of that mineral. But that same state closed 2020 with just over five million tons extracted by two contractors, one of them Chinese. They destroyed more than 75% of its capacity”, says the journalist specialized in the basic companies of Guayana, Damián Prat in his column “Público y Confidencial”.

“Either we learn the lesson that it is not the role of the State to be an entrepreneur, but a promoter of economic development, or we have not learned anything (…) This must be done by the private sector. The potential and value it has is great, you have to look for international partners to do things, you have to put the shares in the hands of a national investment fund as many countries do with the possibility of this being reverted to the people, not to the pockets of any politician,” said Víctor Vásquez, managing director of Palo Grande Casa de la Bolsa.

Making this projection possible requires the intervention of Sidor and the recovery of the Casima Plant (a producer of liquid steel that is later converted into billets), and the briquette kilns.

Vásquez points out that the proposed production levels can be reached by producing all the finished ore in the iron concentration plants that have not yet been completed in Ciudad Piar, Angostura municipality in Bolívar state.

A concentration plant is an industrial facility used to process minerals and obtain valuable metal concentrates. In the case of the steel industry, it is very important because it can improve the quality of material that has a low iron concentration.

“All the iron that is in Cerro Bolívar, which has high levels of phosphorus and 50% iron ore content, if you put it in that plant, a very high quality ore with 67% iron ore comes out, which is super attractive. . It does not compete with mining, you can produce iron and additionally you can produce what the concentration plant would give you, 8 million additional tons,” explained the specialist.

This is followed by repairing the pellet plants of CVG Ferrominera Orinoco, and finishing construction of the pellet plant in which the Venezuelan State invested 425 million dollars through financing from the Heavy and Large Volume Fund of the People’s Republic of China. .

In this context, 15 million tons of direct reduced iron and 12 million tons of steel and rolled products can be produced.

“And we can go further because we have enough reserves to make more plants for concentration reduction and steel production. The possibilities are there, for when we propose it as a country,” said Vásquez.

The engineer stated that the intentions of the study are to glimpse the possibilities of economic development that the country has from the Guayana region.

“It seems essential to us to awaken the awareness that we have that there, that no one has it and that only if we do things right can we enjoy the well-being that this can offer for everyone. We can offer the world and ourselves the possibility of economic development, of converting all the capacity we have for direct reduction into the production of high-quality steel, high-value rolled products,” says Vásquez.

“Our politicians forgot it over time, they used the companies as parking lots for political patronage so that the parties could produce,” he concluded by way of conclusion.

SOURCE:

https://www.bancaynegocios.com/acero-hierro-sidor-palogrande/